The Purpose of Powdered Metal

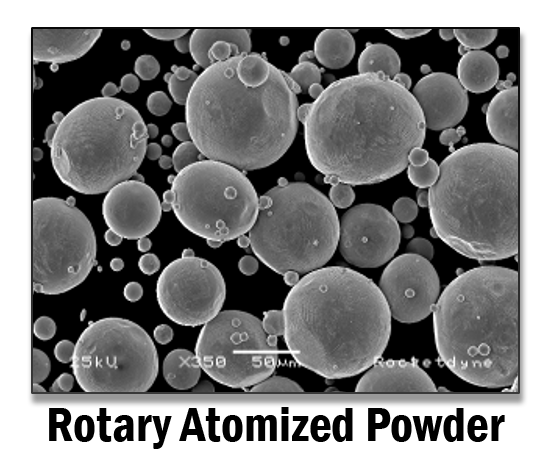

Powder metal assists manufacturers in forming and shaping complex, intricate designs in a uniform fashion. In some situations, this technology offers a cost-effective alternative to mass producing components which require extensive machining during the finishing process. It plays an increasingly important role in modern CNC machining.

Additionally, when correctly sintered, a component formed with the assistance of powder metallurgy demonstrates precision engineering. Metallurgists can often control porosity more effectively using metal powder. This metalworking process provides an excellent way to manufacture some types of gears which require tight adherence to net shape, for example.

The powder metal process involves the generation of far less waste than some alternative fabrication strategies. It may appeal to manufacturers interested in generating high tolerance parts as cost-effectively as possible.

The powdered metal coatings generated with the assistance of powder metal vendors frequently assist manufacturers in obtaining specific desired properties during finishing, also. For example, a company may use this manufacture process to finish a part to achieve improved corrosion resistance.

This process may also give a component’s exterior a desired textural or aesthetic quality. The versatility of metal powdered coatings has contributed to the ongoing increases in the size of this marketplace. In Europe alone, powder metal reportedly generates over six billion Euros in sales activity every year! See more about the details at iqsdirectory.com.

Contact us for more information about powered metal parts manufacturing.