Atomized Powders Produced with High-Vacuum Furnaces/Smelters

The process atomized powders are produced with high-vacuum furnaces/smelters and the application-specific combination of melting and atomization techniques enables production of a wide range of super-clean metal powders, including super-alloys, precious metals, refractory and reactive metal powders. There is a choice in the process between two main atomizer types, namely EIGA and VIGA, for charge weights from 5 kg up to 2500 kg. Customized EIGA and VIGA design variations are available to meet customer specific requirements.

Vacuum induction melting in furnaces/smelters and inert gas atomization is the leading process for production of a variety of high-performance metal powders and essential for quality manufacturing of Ni-based super-alloys as well as Fe-, Co-, Cr-based and other special alloy powders. The vacuum induction melting unit is integrated with an inert gas atomization unit. The starting materials are melted using electromagnetic induction which couples electrical power into the crucible/material under vacuum or in an inert gas atmosphere.

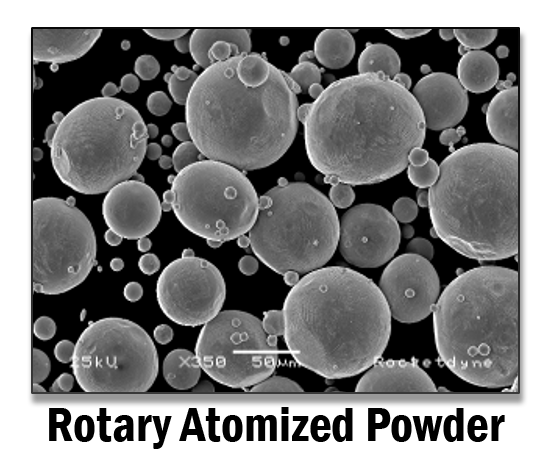

Atomized powders produced have the following characteristics:

- Spherical shape

- Good rheological flow characteristics

- Particle size ranging from 30 µm ≤ d50 ≤ 90 µm

- High purity & High flow ability

- Low O, N, and H concentrations

- Rapidly solidified and homogeneous microstructure

Materials and Metal powder applications

The process atomized powders being produced with high-vacuum furnaces/smelters are the most versatile method for processing a variety of metallic elements and alloys into metal powders.

Contact us for more information about atomized powders produced with high-vacuum furnaces/smelters.