Evacuation of PM Capsules

Vacuum

A vacuum is achieved when molecules of gas (like oxygen and nitrogen) are removed from a sealed volume that leaves a partial vacuum. Atmospheric pressure is measured at 760 torr (14.7 PSI) or 1 Bar. We pump down all of our parts that we manufacture as part of our process. Depending on part characteristics we evacuate our capsules to a pressure of 1×10-3 torr. In some specific cases, even down lower to a pressure of 1×10-6 torr.

A capability to evacuate our parts is essential to achieving and surpassing your expectations. We have numerous vacuum pumping stations. Some attached to tables that will vibrate powder, some attached to furnaces. The types of our in-house repaired and serviced pumps include:

- Rotary Piston Vacuum Pumps (large volumes)

- Rotary Vein Vacuum Pumps (medium to small volumes)

- Roots Blower (booster) Pumps

- Diffusion Pumps

- Turbo-molecular Pumps

No down time!

At Synertech PM, we have our own team of engineers and repair technicians that maintain, repair, and service our vacuum pumps. This minimizes down time and provides alternating systems that can be swapped in at any time.

High and Ultra-High Vacuum Systems

Integral to our process is how we purify our powder metal parts. By using a combination of rotary vein + booster vacuum pumps, we evacuate all of our capsules to a pressure of 1×10-3 torr.

We even have the capability to achieve 1×10-6 torr with our diffusion pumping systems.

Vacuum Filling of PM HIP Capsules

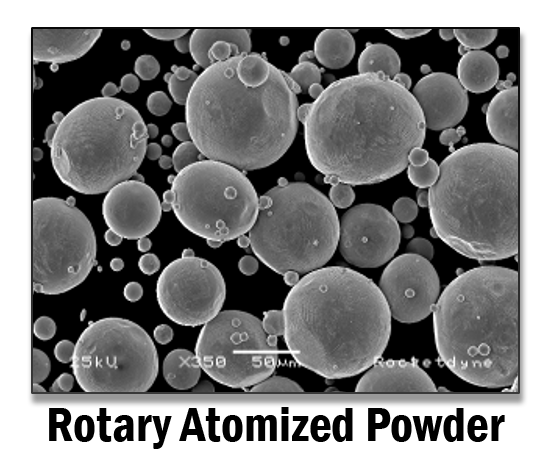

Protecting powder metal from corrosive constituents found in our atmosphere (air) is easily done with our vacuum filling stations. We even have arrangements with our powder suppliers.

This guarantees that when the powdered metal is produced (atomized powders are produced with high-vacuum furnaces/smelters) and filled into large vacuum tight drums or what we call hoppers. The hopper has a high-vacuum grade valve built onto it.

Which we utilize to ensure that the powdered metal never come in contact with the air. Further, our facility and equipment is suited for any scalability. From a small single hopper to a large many.

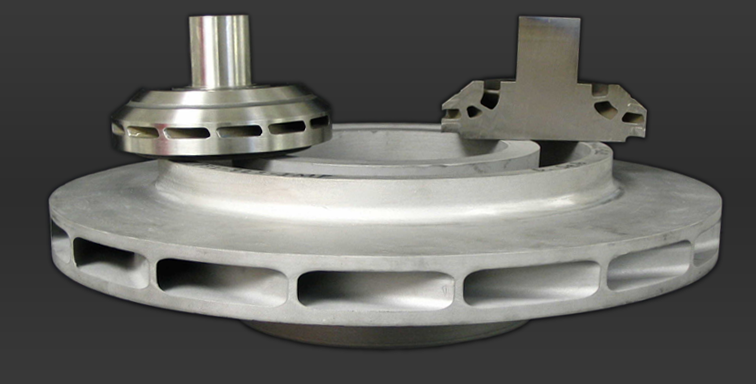

This is important for high fatigue resistant applications and rotating parts.