Ti PM HIP

Synertech and LNT can produce and supply PM HIPed Ti 6-4 blanks (regular shapes and Near Net shape (NNS) preforms) for machining with the excellent lead time of 5-6 weeks at competitive prices under AMS 4994 and ASTM B265-11 using cost efficient Ti 6-4 alloyed powders, but for applications not requiring special specs (like Honeywell or Boeing), i.e. for military, rockets, electronics, chemical industry, power generation and commercial applications.

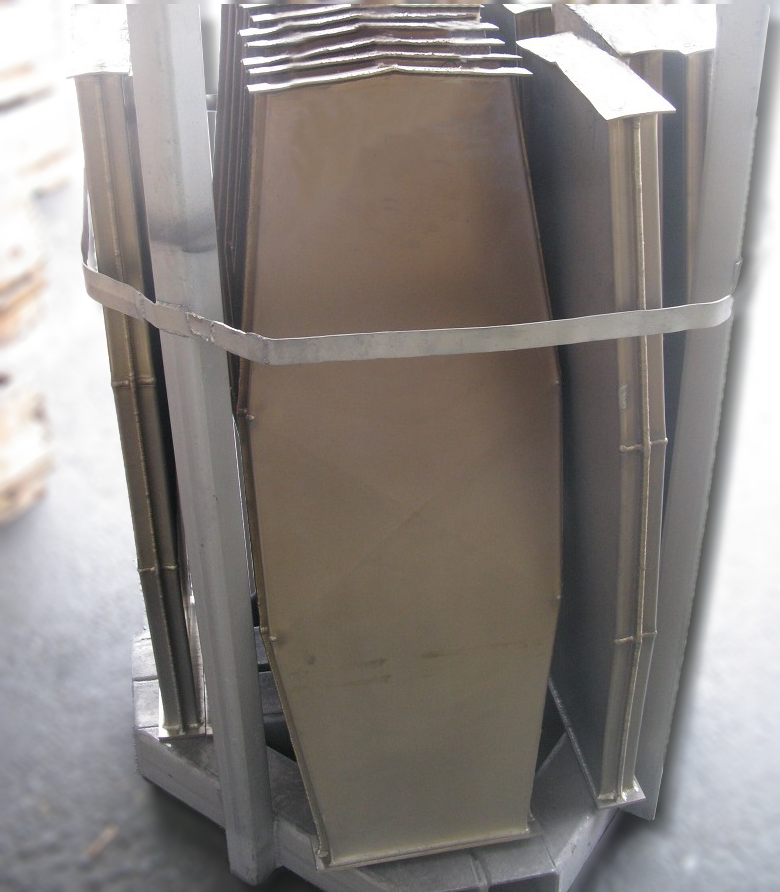

Complex Shape **17″ Tapered D Ti-64

Tubular Shapes

We had started this initiative 15 years ago with Rolls-Royce and they had confirmed higher design allowables for the PM HIP Ti 6-4.

Our typical mechanical properties compared to ASTM B265-11 are:

| TEMP | DIA. | AREA | YIELD | YIELD | ULT | ULT | ELONG | R.A |

| RT | .248 | .0483 | 6052 | 125 | 6605 | 137 | .15 | 27 |

| RT | .250 | .0489 | 6139 | 126 | 6689 | 137 | .15 | 26 |

| – | – | – | – | REQUIREMENTS | – | – | – | – |

| RT | – | – | – | 120 | – | 130 | 10.0 | – |

The typical chemical composition can be provided by request (Material Certificate MC-19-0971)

The typical micro-structures are

As HIPed (1650F, 3 hours) condition

HIPed and annealed (1350F, 4 hours) condition

and the need of Mill Anneal is debatable as there is no need to homogenize the material, but just in case , this can be done.