Hot Isostatic Pressing

A volumetric pressing process involving inert gasses

Consolidation to eliminate porosity and to achieve up to 99.998% relative density.

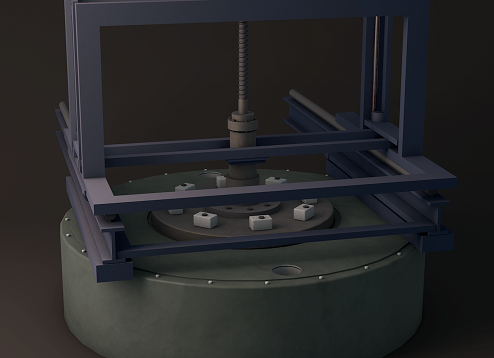

An integral step to our process is referred to as HIP. Hot Isostatic Pressing involves loading parts into a large cylindrical pressure vessel. That vessel is pressurized with an inert gas such as Argon, simultaneously temperature is ramped from room temperature up to 2300 degrees farenheit.

Numerous industries include HIP; The medical industry relies on HIP heavily to sterilize and eliminate porisity in equipment. While the automotive industry will send metal castings to push properites beyond the green state.

For our PM process, we use HIP to consolidate powder metal from a granular state to a solid state. Dislocation occurs between the powder particles and the material is fused together. The high pressure and temperature combination ensures complete consolidation-therin eliminating porosity and maximizing properties.

The properties that excel with our process include but are not limited to: Hardness, Tensile Strength, Ductility, and Density.

Why PM HIP?

- Near-net shape and complex components (reducing material cost and machining)

- Alternate supply route, shorter turn-around times

- Considerable EPRI/Industry development over the last 5 years

- Ideal for multiple penetration applications (RPV or CNV head) vs expensive forgings

Inspection, Costs?

Inspection, Costs?

- Homogeneous – Excellent inspection characteristics

- Costs roughly equivalent to forging

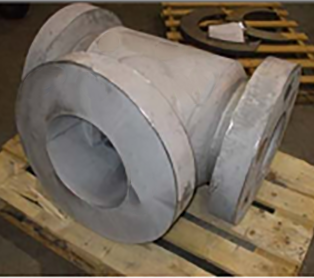

Partial RPV Ring Section

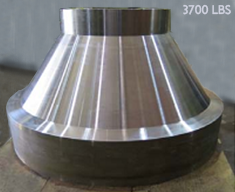

3700 LBS BWR Nozzle

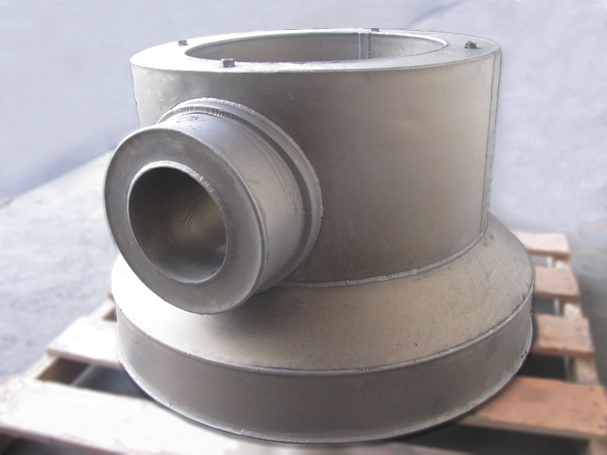

Large 316 SS Valve Body