Diffusion Bonding as a Joining Technique

Diffusion bonding is typically utilized for ferrous parts which are fairly small in size. Hence, part geometry can be a concern. To avoid this complication, sintering and diffusion bonding can potentially be carried out in the same furnace.

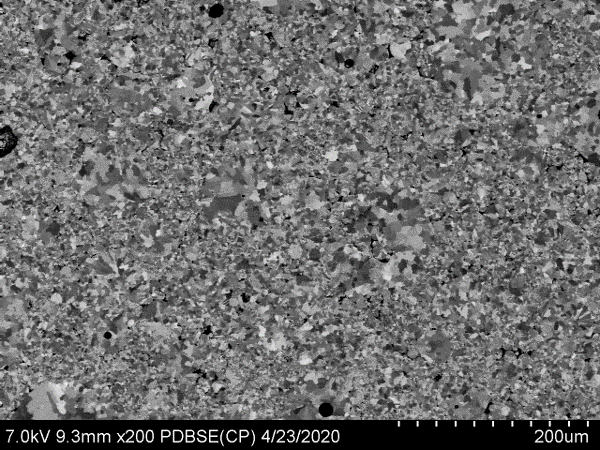

Diffusion bonding is the solid state joining of two surfaces under intimate contact and under high pressure and temperatures resulting in an undetectable original bond line, as grains from the two original parts form common boundaries along the original bond line.

Diffusion bonding is a solid-state bonding process used as a joining technique. The metal components being joined undergo only microscopic deformation, and the joining region is homogeneous – without secondary materials or liquid phases. The process includes diffusion bonding of titanium, steel and copper alloys used in the fabrication of several aerospace components with various complex configurations.

The diffusion-bonding method can be successfully used with blow forming to form near-net shape aerospace components, including high-pressure tanks for attitude control of spacecraft, a combustion chamber with copper cooling channels and lightweight structural panels.

Diffusion bonding uses the approach that components are held under load at elevated (below melting) temperature in a protective atmosphere or vacuum. Solid phase diffusion bonding (SPDB) is one variant of the process, although transient liquid phase diffusion bonding (TLPDB) is a more successful approach.

Information Reference: https://www.sciencedirect.com/topics/engineering/diffusion-bonding F.L. Matthews, in Encyclopedia of Materials: Science and Technology, 2001

Contact us for information about Diffusion Bonding services.