Our capabilities

Our combined 100+ years of engineering experience means we can design and deliver the highest quality powdered metal parts.

Our advanced engineering knowledge helps manufacturers find ways to replace slow or inconsistent forging and casting methods with better-performing alternatives, which has proven to give our customers faster lead times without sacrificing quality.

Whether your application requires diffusion bonding, densification, cladding, welding, or machining, our engineers will work closely with you to deliver to your highest satisfaction.

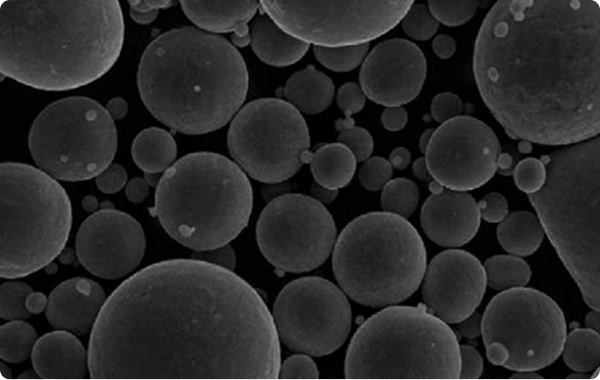

We specialize in powder metallurgy

Powder metallurgy is the blending of fine powdered materials and then pressing them into the shapes or forms (compacting) that you need for your project. Then, you heat the compressed material in a controlled setting to bond the material (sintering to the metal).

It provides many advantages over other metal-working technologies, such as cost-effectiveness, flexibility, and a high part-to-part uniformity.

Powder metallurgy parts are used in many types of products, including hardware components, automobile parts, power tools, postage meters, knives, oil and gas drilling well-head components, and more.

Powder metal pressing is an essential part of the powder metallurgy process, and we have extensive expertise in two types:

HIP is a volumetric pressing process involving inert gases that consolidates powder metal from a granular state to a solid state. This process helps eliminate porosity and achieves a relative density of up to 99.998%.

The properties that excel with our process include, but are not limited to: Hardness, Tensile Strength, Ductility, and Density.

We use CIP for pre-pressing elementary or blended powders. CIP can be used in conjunction with PM HIP processes or pre-sintering applications. The working dimensions are 12″ in Diameter by 30″ tall.

We have a dedicated Cold Isostatic Press that can press up to 40,000 psi, which means we can process a large number of parts simultaneously or singular large parts.

We also offer these capabilities to enhance quality and minimize defects

Diffusion bonding is typically used for ferrous parts that are fairly small in size. Hence, part geometry can be a concern. To avoid this complication, sintering and diffusion bonding can potentially be carried out in the same furnace. Similar to brazing, diffusion bonding has also found applications in HIP components.

We have several methods for mixing two or more powders for various needs. For small-batch processing, we can use a small ball mill that mixes powders of dissimilar weights to a uniform and even distribution.

Large-scale mixing is also available using one of our V-shaped blenders or drum blending horizontally or at a 45-degree offset.

The main advantage of powdered metal HIP versus traditional powdered metal press and sintering technologies is that the initially loose powder in a HIP capsule is subjected to the combined action of pressure and temperature during the HIP cycle.

This results in virtually no voids throughout the material, resulting in a uniform, fine-grain, microstructure.

For all of our capsules, welding is fundamental. Having reliable welders that produce welds that can survive theoretical conditions allows us to have welded bodies that survive permeable helium detection and the intense process of Hot Isostatic Pressing.

We offer GMAW and SMAW welding for any applications that you may require.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

We conduct our own in-house, non-destructive testing of our capsule elements and welds in accordance with the American Society for Testing and Materials Standards (ASTM-E-165 Standard Practice for Liquid Penetrant Examination for General Industry).

All of our parts undergo leak testing, ensuring that our capsules will withstand the massive pressures of Hot Isostatic Pressing.

Contact our team to get started on your project today.

Partner with Synertech PM.